RV's, Campers, Boats and Toys Parking Pad Page

Welcome to our RV, Camper, Boat and Toy Parking Pad Page. We have put all the materials that can be used to do your project to make a long lasting, well drained parking area for your favorite weekend recreational vehicle on one page. These materials will work well for pickups, mounted and pull type campers, motor homes, motorcycles and their trailers, boats, personal water craft and snowmobiles and trailers. Call us at 720-298-0948 for additional information and a no cost or obligation material and delivery Bid.

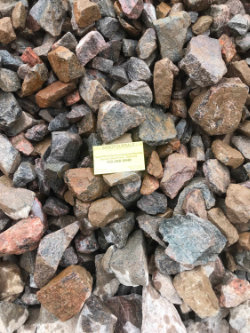

Image 1. 15 ton pile of Class 6 Mountain Granite Roadbase. Image 2. 15 ton pile of Class 6 Recycled Concrete Roadbase. Image 3. 15 ton pile of Recycled Asphalt Roadbase. We sell and deliver all products needed for your project.

Class 6 Granite Roadbase. - $21.95 per ton.

Class 6 Recycled Concrete Roadbase. - $21.95 per ton.

Recycled Asphalt Roadbase. - $22.95 per ton.

1"- 1-1/2" Recycled Contractors Rock. - $23.95 per ton.

1-1/2" Mountain Granite Rock. - $39.95 per ton.

3/4" minus Mountain Granite Rock. - $39.95 per ton.

4" Ave Mountain Granite Rock. - $41.95 per ton.

Now is the time to install your RV, camper or toy hauler parking pad. Soon we will be getting rain and snow that will make the project more difficult and time consuming. Each city and county has different rules and regulations for new parking pads and driveways, depending if they are visible from the street and are in the property yard. You should check with them before beginning your project.

While each type of roadbase has many uses, specific types of roadbases work better in different situations. Class 6 Granite roadbase is the best overall material to build your parking pad with. It works better on freshly graded dirt. Poorly drained areas where standing water may be an issue, on sandy or clay soils, because of the amount of aggregate and binders in it.

Class 6 Recycled Concrete Roadbase works well installed over freshly graded dirt, as a top layer over existing base of material and in some situations over clay soil. It doesn't work quite as well in sandy, mucky clay or poorly drained areas.

Recycled Asphalt roadbases does not usually meet the specification recipe for Class 6 Roadbase due to the varying amount of aggregate in some of the asphalt that was crushed. The tradeoff is that freshly crushed and screened asphalt compacts well over newly graded dirt thats been compacted and will stay compacted, depending on the traffic and how the snow is plowed. It works over clay soils at a 4 inch or thicker depth. It will disappear in sandy soils.

What is Class 6 roadbase? Class 6 is a (specification or Spec or recipe) for 3/4 inch minus roadbase. That means that the size of the largest aggregate in the material is 3/4 inch rock, then 1/2 inch rock, then 3/8 inch rock and then the fines. In Granite road base it consists of granite fines, in Recycled Asphalt it contains asphalt fines, and in Recycled Concrete it contains concrete fines. Granite roadbase meets this, Recycled Concrete roadbase sometimes meets it, Recycled Asphalt roadbase seldom meets it.

What are the different types of Road Base available? The Roadbases we sell the most of are:

Granite Class 6 Roadbase

Recycled Concrete Roadbase

Recycled Asphalt Roadbase

Due to the pandemic there is often a shortage of Recycled Asphalt and Recycled Concrete. We have mountains of Granite Roadbase, no pun intended.

Class 6 Granite Roadbase. - Direct from the gravel pit Roadbase. The fresher the material, the better it compacts and stays compacted.

Class 6 Granite Roadbase. - The material is engineered to allow for greatest compaction and durability.

Class 6 Granite Roadbase. - Delivered and ready to be spread out to form a continuous, gradeable surface suitable for parking and preforming vehicle maintenance on.

Class 6 Granite Roadbase. - 15 tons Granite Roadbase delivered for a parking area. The material in the picture will cover the entire area 2-3 inches deep.

Class 6 Granite Roadbase. - Granite roadbase placed within bounderies and leveled and compacted.

Class 6 Granite Roadbase. - Notice the trailer parked on the surface. No problem here.

Class 6 Recycled Concrete roadbase. - 15 ton load of Recycled Concrete Roadbase delivered for a home driveway.

Class 6 Recycled Concrete roadbase. - Class 6 Recycled Concrete Roadbase right out of the truck. The quarter shows the different sizes of rock in the mix.

Class 6 Recycled Concrete Roadbase. - Compacted Roadbase of any type will stand up to the water from washing your vehicle but you will need to either crown the center of the pad so the water will drain to either side instead of pooling on top of it, or it may be easier to slope the pad slightly (just a couple inches) to the downhill side and create drainage that way.

Class 6 Recycled Concrete Roadbase. - Parking pad watered down and compacted with drainage (slope) towards the street. This is a hard, durable surface tht will stay in place.

Recycled Asphalt. - Recycled asphalt is an engineered product that when spread out and compressed will form a hard surface. It can be combined with Contractor's rock to create a very hard and durable surface that is long lasting.

Recycled Asphalt. (pile) - The material is delivered in piles, ready to be spread out.

Recycled Asphalt. (spread out) - This picture shows the initial pass of material. The material is best spread out with a small tractor or bobcat and compacted in place.

Recycled Asphalt. - This is also an engineered product designed to form a hard durable surface wen compacted and set up.

Recycled Asphalt over Contractor's rock. - 1"-1-1/2" Recycled Contractors rock spread over a clay driveway at a new modular home site.

Recycled Contractors rock is the best material for a freshly graded driveway over poor soil of any type.

Recycled Asphalt over Contractor's rock. - Class 6 granite roadbase is placed over Contractor's rock and compressed to form a very hard and durable surface.

The property is pure clay. With 2 different 4 wheel drive cars, the homeowners still had a hard time getting in and out of their property. Since the material has been applied, it is as hard as any driveway in the county.

Recycled Asphalt over Contractor's rock. - Once these materials heat up, they form an interlocking surface that sets up very firmly.

4" Multi-Colored Mountain Granite. - Our 4 inch average (2 inch - 6 inch) Mountain Granite Rock will work as both a base for your parking pad, under Roadbase on sandy or poorly drained clay soil, as a washing pad for your camper or any other vehicles or the entire parking pad. It is very attractive as well as functional, although until it is driven over a few times it can be hard to walk on.

4" Multi-Colored Mountain Granite. (wet) - It does cost more than the roadbase, but it will drain better than any other material, last forever, and if it ever washes away, you'll have far bigger problems to worry about than your RV parking pad.

It is $39.95 per ton, 1 ton covers 32 square feet, 1 layer deep. We have an 8 ton minimum delivery.

4" Multi-Colored Mountain Granite. (dry) - This is what it looks like dry. This material will not move once placed.

4" Multi-Colored Mountain Granite. - We hand pick each pile and then mark them for delivery.

1-1/2" Contractor's Rock. - 1"-1 1/2" Recycled Contractors Rock. This Rock ranges in size from just under 1 inch to just over 1-1/2".

1-1/2" Contractor's Rock. - This pictures shows the different sizes of the rock as well as the rough edges that help it to bind together to make a solid surface on sandy and clay soils. It is not magic material, but is will save you from loosing a tremendous amount of roadbase over the years.

1-1/2" Contractor's Rock. - Straight off the truck and spread out to form a road.

To get the full benefit from any kind of roadbase installation; asphalt, concrete or mountain granite, it must be installed at a minimum 2" depth; but no thicker than 4 inches. Level it out by machine or hand, spray a fine mist of water on it and compact it by compactor or your heaviest rubber tire vehicle; RV, SUV, Pickup. Not a tractor or skid steer loader. The lug tires don't compact the area uniformly and you may end up with some spongy spots that will be a real problem in wet weather. If installed and compacted correctly, with average use, this parking pad should last 8-10 years.

Materials Not to Use for an RV, Toy Hauler or Boat Parking Pad

All of the materials above on this page will work well, either by themselves or in combination.

Here are a few materials you probably don't want to use:

When in doubt about the best material for your project, please feel free to call us at 720-298-09848 or submit a Bid through the Request a Bid button on the top of this page.

We'll be glad to help you figure out which material works best for your situation and will give you an exact price material and delivery bid to your home. We strongly recommend that you consult your cities or counties website when planning your project to make sure both your project and the materials you want to use are acceptable to them.

You need 96 tons for an average depth of 2 inches, You will need 144 tons for a 3 inch average depth. Calculations are shown below.

| Tonnage Example - Use calculator below to determine amount needed | |||||

|---|---|---|---|---|---|

| Product | Length | Width | L x W =SF | SF / Depth | Tons |

| Arena Sand / Squeegee | 120 Feet | 80 Feet | 9600 | 100 | 96 |

To Order the Correct Amount of Material

Measure the length and width of the area to be covered. If you don't have a tape measure, walk the length and width of the area. Figure each full step as 2 1/2 feet. Get the total square footage of the area by multiplying the length by the width.

Example: 120 feet long by 60 feet wide = 7200 square feet

1 ton of Washed Sand covers 100 square feet 2 inches deep.

For every 2 inches of depth you will need 72 tons of Sand

Please note: This is only a rough indication of the amount of material you may need. Actual dimensions may vary due to irregularities in soil types and established rough grade.

Once you determine your material and amount needed, call us at 720-298-0948

Or use the Contact page to arrange for delivery and pricing.

We take Paypal, Visa, MasterCard, American Express and Discover.

We take Paypal, Visa, MasterCard, American Express and Discover.